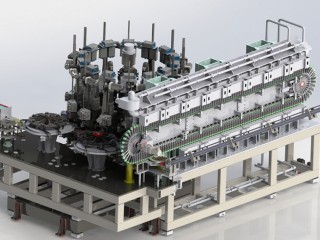

Stretch Blow Moulder

Jun 30th, 2024 at 10:53 OUR SOLUTIONS RPT 243 views Reference: 261Location: RPT

- The system is industrial PC electonic controlled.

- The bottle production parameters can be called immediately so the bottle change is so practical.

- It is very easy to follow the machine and operator intervention with 15’’ coloured TFT Touch Screen.

- It has the qualification of immediate intervaton through internet to the customer process problems due to having Industrial PC ethernet portal.All process like the temperature can be adjusted through Industrial Pc. It is equipped with the security covers in European norms.

- The bottle volumes are all volumes between 0.25LT – 2.0LT

- Process follow up system with the independent pressure time graphic for all molds .

- Very sensitive blowing process with pre-electronic servo controlled tensioning system

- Transfer process without waste with preform transfer group and electronic servo controlled clamp

- % 10 additional energy saving with 60 mm axis gap oven wheel system Uncut and rapid production with the constant oven system

- Machine design with no mechanical cam, low maintanance design, sensitive and more silent machine structure ı

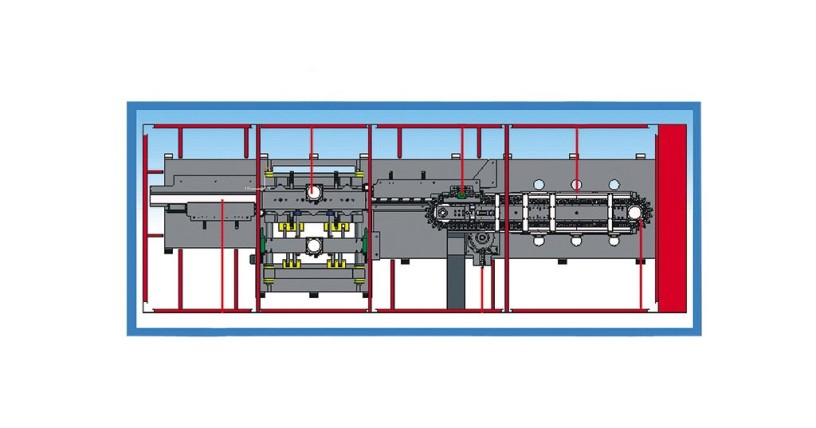

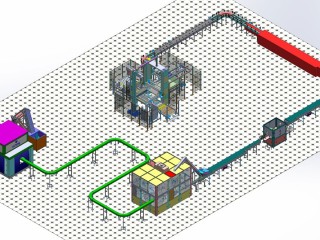

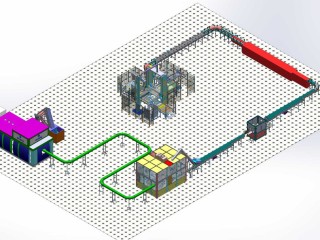

Preform feeding

Star wheels which is controling by servo motor provide feeding preforms to the system . The stars can be easily changed according to the different bottles neck

Preform transferring

The movement of the preforms through heat chain controlled by servo motor

The system can handle preforms which have neck diameter up to 48 mm

Heating

Preforms are heated through resistance . during the movement of the preform through heat chain , air and water circulation provided to prevent the heat effect on the necks

Transferring To Mould

Heated and ready preforms are withdrew inside the mould . this function controlled also by servo motor.

Blowing

İn this stage the mould which has specific and longer life structure is clamped to able blowing the preforms through customised shafts for each cavity

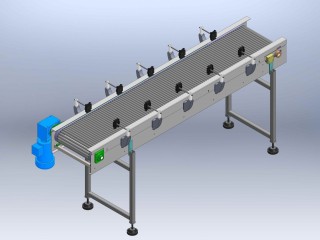

Output

The bottles will be sent directly to conveyor .

| Model | Capacıty |

|---|---|

| BLW2C2-SRV | 0.25 lt up to 2 lt - 3000 BPH |

| BLW4C2-SRV | 0.25 lt up to 2 lt - 6000 BPH . |

| BLW8C2-SRV | 0.25 lt up to 2 lt - 12.000 BPH |

| BLW13C2-SRV | 0.25 lt up to 2 lt - 18.000 BPH |

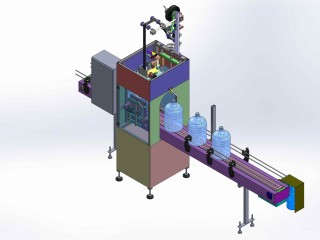

5-10 lt. Pet Blow Moulder

| Model | Capacıty |

|---|---|

| BLW2C10-SRV | 5 lt up to 10 lt - 2000 BPH |

| BLW4C10-SRV | 5 lt up to 10 lt - 4000 BPH |

| Model | Capacıty |

|---|---|

| BLW1C19-SRV | 19 lt - 500 BPH |

| BLW2C19-SRV | 19 lt - 1.100 BPH |