P.C Bottles Filling

Jun 30th, 2024 at 11:22 OUR SOLUTIONS RPT 146 views Reference: 267Location: RPT

P.C Bottles Filling

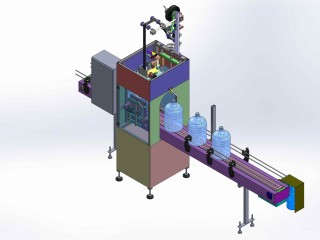

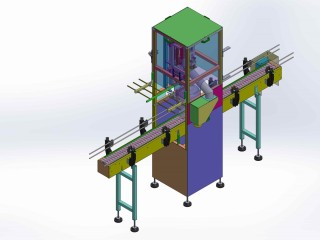

This machine provide perfect internal cleaning , filling , capping P.c bottles with out any overflows

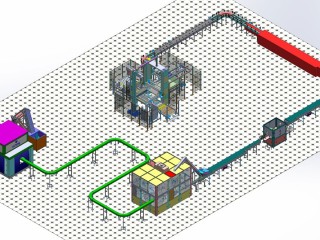

Overview

This machine provide perfect internal cleaning , filling , capping P.c bottles with out any overflows

All the surface which contact with water made off stainless steel AISI 316 ,with CE certificate

the process & process time controlled by PLC , through the display monitor you can enter the parameter and read error mesages

Sections

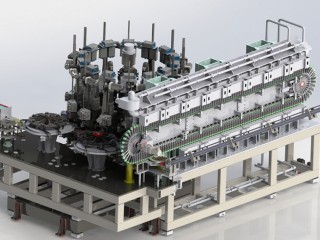

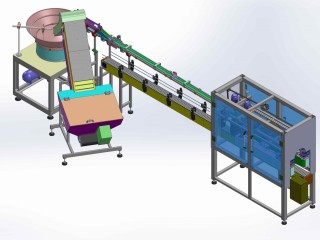

Washing Group :

Bottles feed is done in horizontal way, after that go through 16 ,20,30 internal washing stations (according to the client demmand ) as following : prewashing , wash with warm medicated water, ozonated water, disinfectant, ozonated water, washing is carried out in six stages, including the last rinse Filling Water.

+ The discharge washing water of each stage go to lower tanks and the system prevent the washing water of each stage be mixed

+Due to the structure of the machine The washing process is done in closed area with fully sealed Windows

+ Through easy open covers , cleaning the tanks will be done easily

+ Using hot water which heated by resistance or steam are made according to customer demand.

+the motion of the nozzles in the medicated hot water washing stage provide cleaning inside the bottle and reched to all parts inside the bottles and cleaned it

+ After washing the inside and outside of the bottle it return to the tank through a sieve.

İn the last stage of the internal washing stations the botlles are rinsed by pressing the booster pump

and automatically transferred to the filling unit . Water goes directly into the pre-wash station in the station. Thus, water savings are done

Filling Unit

+ P.C bottles upload as Horizontal and automatically way to Wash socket and cleaned through 16 stations.

+ The P.C bottles become upright position at the filling group and centrilized under filling nozzles

+Filling tank have 2 pumps (slow – fast ) so the filling is done and controlled without overflow

+Each nozlle have 3 actuators valves controleed by PLC and provide the filling without overflow (according to client demand it can be made flowcontrol system)

+The filler group has glass covers so monitoring the process is availabele and this covers opened easily

+ that carry air to enter into the body to prevent the outside air that HEPA filter system has been positive.

+By applicate positive air through HEPA filtir system , prevent Dirt and micro-organisms to enter inside the machine

Rotary and linear type is available

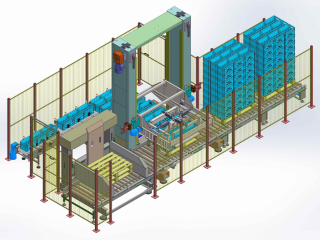

Closing Unit

+ the conveyor which stopped during filling will be move after fillng process is finished and let the bottles pass to the clouser unit

+ the orientor let the capps go through the rail then it is taken from the channel by the end of the Bottles

+ caps washed by ozonated water (O3) during their going to the bottles

+ the process is done in closed ares and untouched . the process & process time controlled by PLC , through the display monitor you can enter the parameter and read error mesages

Capacity

| Model | Capacity |

| Rinsing-Filling-Capping CPW-1 | 250 - 230 |

| Rinsing-Filling-Capping CPW-2 | 450 - 430 |

| Rinsing-Filling-Capping CPW-3 | 720 - 700 |

| Rinsing-Filling-Capping CPW-4 | 960 - 900 |

| Rinsing-Filling-Capping CPW-5 | 1200 - 1100 |

| Rinsing-Filling-Capping CPW-7 | 1600 - 1500 |

| Rinsing-Filling-Capping CPW-10 | 2400 - 2150 |

| Rinsing-Filling-Capping CPW-10 -26 | 2000 - 2200 |

Video