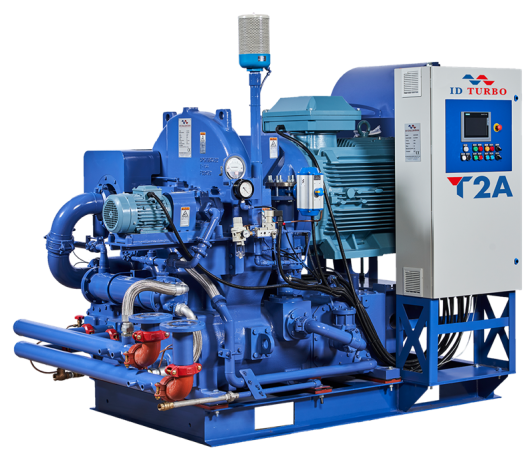

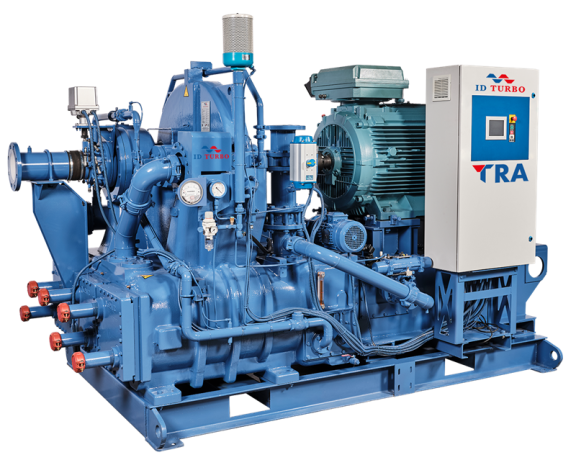

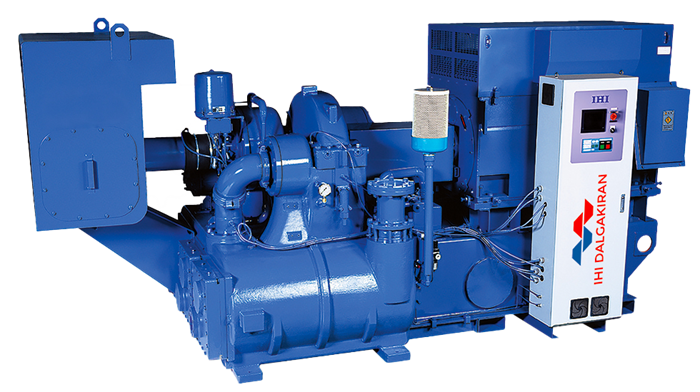

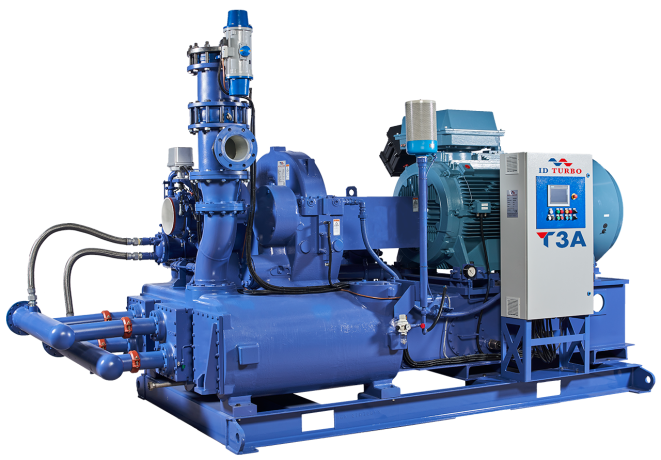

Turbo Compressors

Jun 23rd, 2024 at 13:39 Compressed Air Systems - أنظمة الهواء المضغوط RPT 188 views Reference: 112Location: RPT

Energy Saving

For the stringent energy-saving requirements, we face today, IHI ID provides high-level energy savings with turbo compressors using advanced rotary machine technology that provides first-classenergy efficiency.

User Customization

In the manufacturing facilities, compressed air needs are constantly changing. IHI ID Turbo Compressors are specially designed based on our customer needs, factory location and climatic conditions to provide the best solution for production operations.

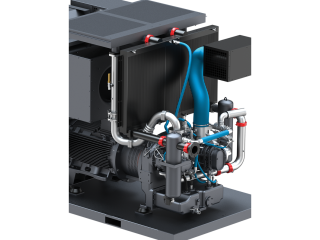

Compressor Frame

The gear case and air coolers are cast together in a single, construction.

The robust and compact compressor unit and air paths are surrounded by a thick, seamless wall that is also highly effective in reducing noise level and inernal pressure losses.

Impellers

Designed with the power ofa deep-rooted engineering experience, impellers provides the upper segment efficiency and wide operating range for users with the support of CFD technology. They are resistant to structural constraints such as corrosion and particulate abrasion, thanks to Titanium structures.

Diffusers

The kinetic energy generated by the impeller in the rotational motion enhances the system pressure by converting it into potential energy as the flow passes through the diffuser. The air flow passing through the diffuser and impeller is simulated in a coupled manner in the CFD environment to obtain a low turbulence flow profilewith minimum lossand quiet.

IGV (Inlet Guide Vanes)

The compressor’s inlet has vanes whose angles can be change in order to reduce the impeller air intake.

This is more effective than using a butterfly valve to add pressure loss in order to reduce airflow, and if the same airflow is discharged, the dynamic power can be kept low.

Tilting Pad Journal Bearing

In order for the high speed pinion shafts to be able to bed efficiently, they provide an even distribution of radial loads. They do not need maintenance and replacement under normal operating conditions.

Labyrinth Seal

Labyrinth seals are preferred to ensure sealing between the pressure chamber and the gearbox.

The labyrinth seals provide sealing without touching the shaft. Hence it removes the friction losses due to sealing and does not need maintenance.